Grain, Seed & Fertilizer Handling

Custom Seed Handling Systems That Fit Your Farm

Grain quality doesn’t come easy – and once it’s in the bin, the last thing you want is to lose value through damage, delays, or bottlenecks. That’s where a well-built seed handling system comes in. Whether you’re moving, cleaning, or storing seed, the right setup keeps things flowing smoothly and protects your grain investment.

At Current Group, we design custom seed handling systems that fit your operation – not just any farm. Every acre, every crop, and every bin counts. And with the right automation and electrical work behind it, your system does exactly what you need, season after season.

Why Seed Handling Matters on Today's Farm

When you’re managing thousands of acres, even small inefficiencies add up – lost time, damaged grain, higher labour costs. A poorly designed or outdated seed handling setup can drag down productivity across your entire farm.

Here’s why more Western Canadian farms are investing in smarter seed systems:

- Efficiency: Load, unload, and clean faster without rework

- Preservation: Reduce seed damage and maintain germination quality

- Scalability: Systems designed to grow as your operation grows

- Labour savings: Fewer manual processes mean fewer costly mistakes

- Automation: Integrate with bin monitoring, conveyors, and augers

Farmers don’t just need equipment – they need systems that make sense for how they run their day-to-day.

Solutions

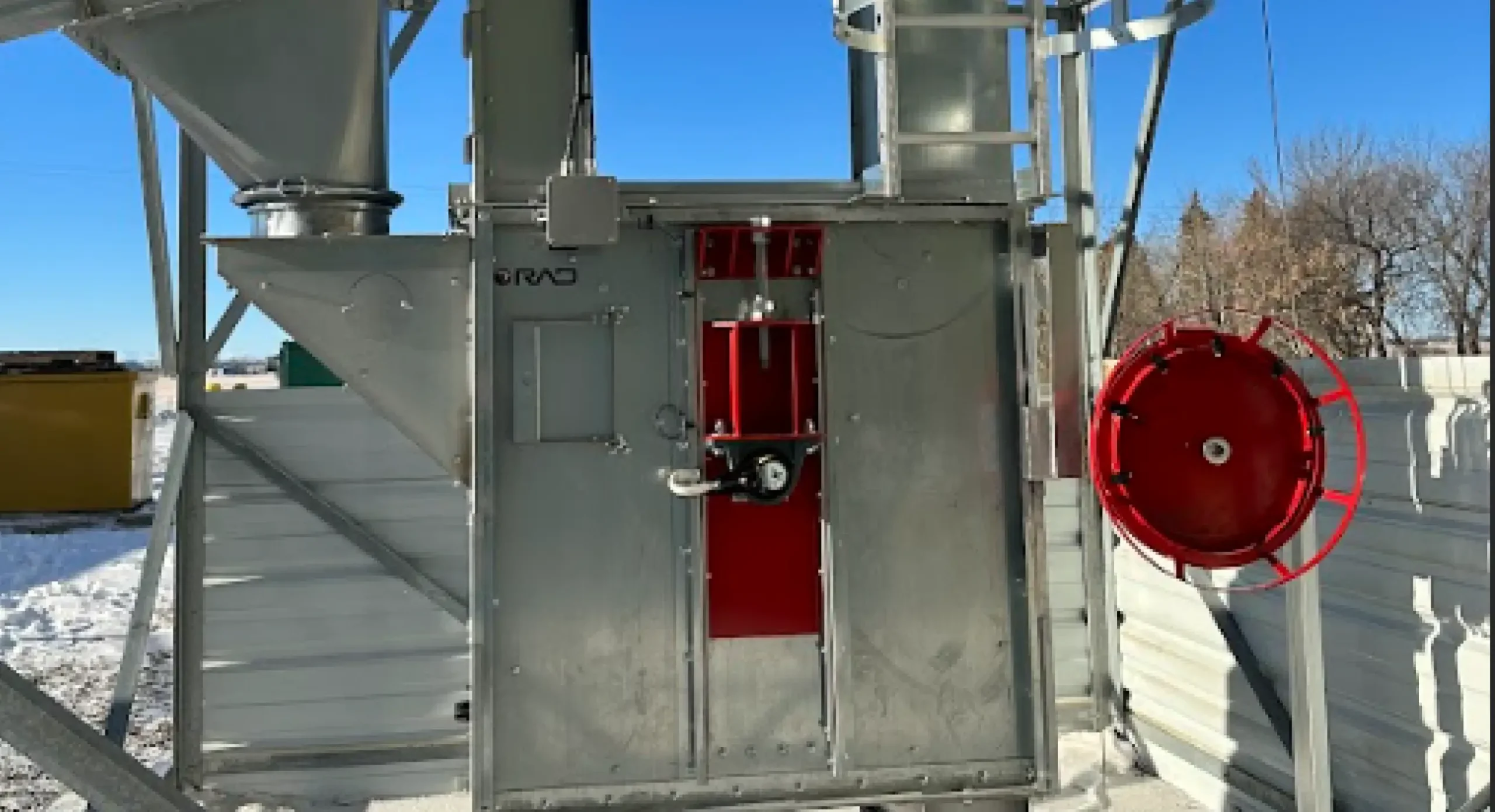

Automated Handling System

Installing automated grain, seed, fertilizer, and feed handling systems to ensure efficient, safe and space-saving seed transfer to designated bins.

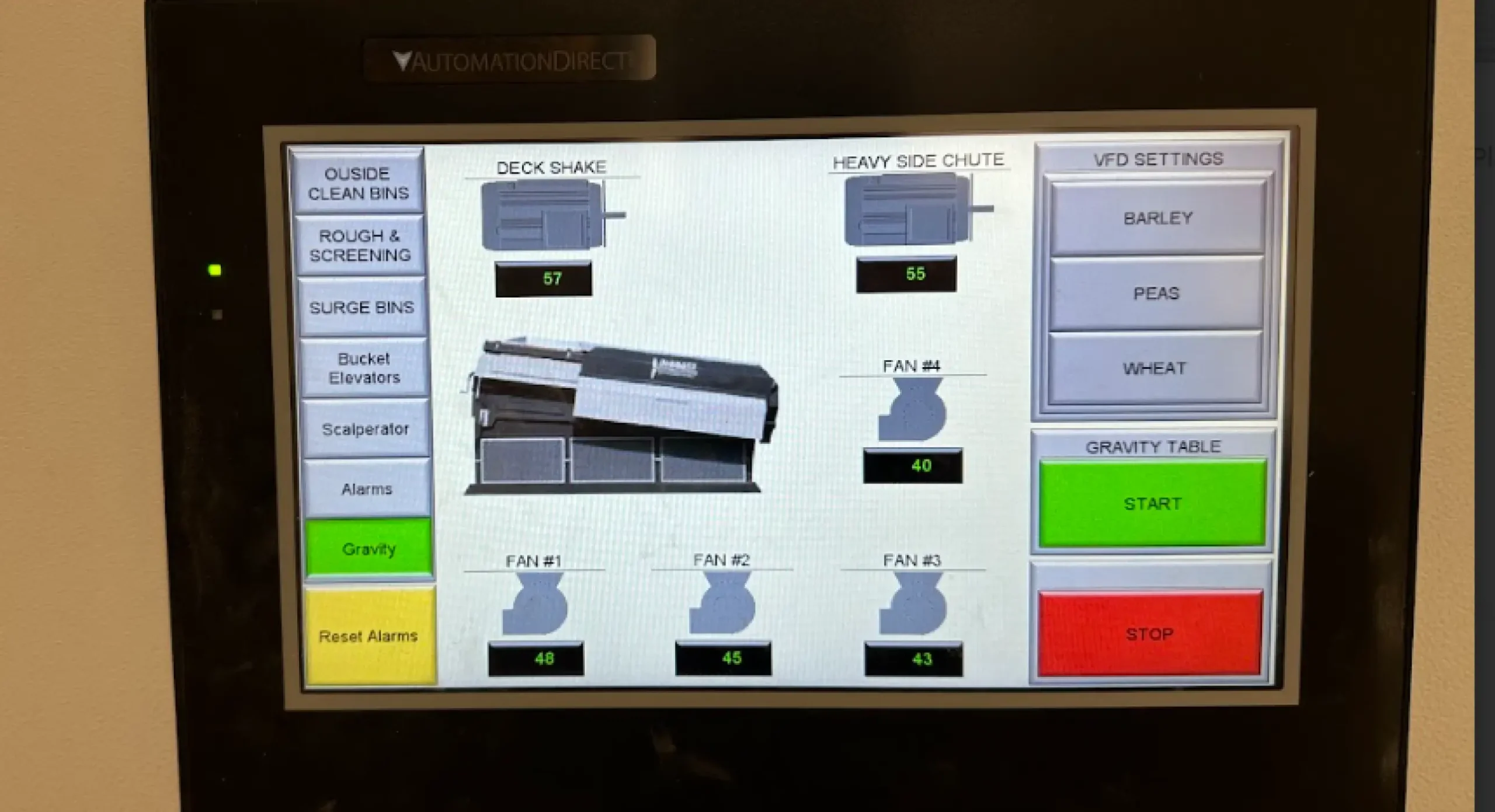

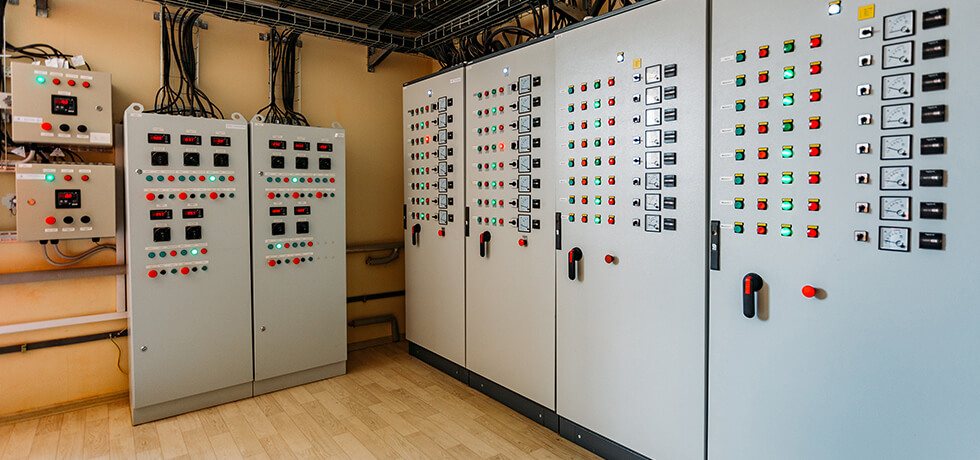

Integrated Control System

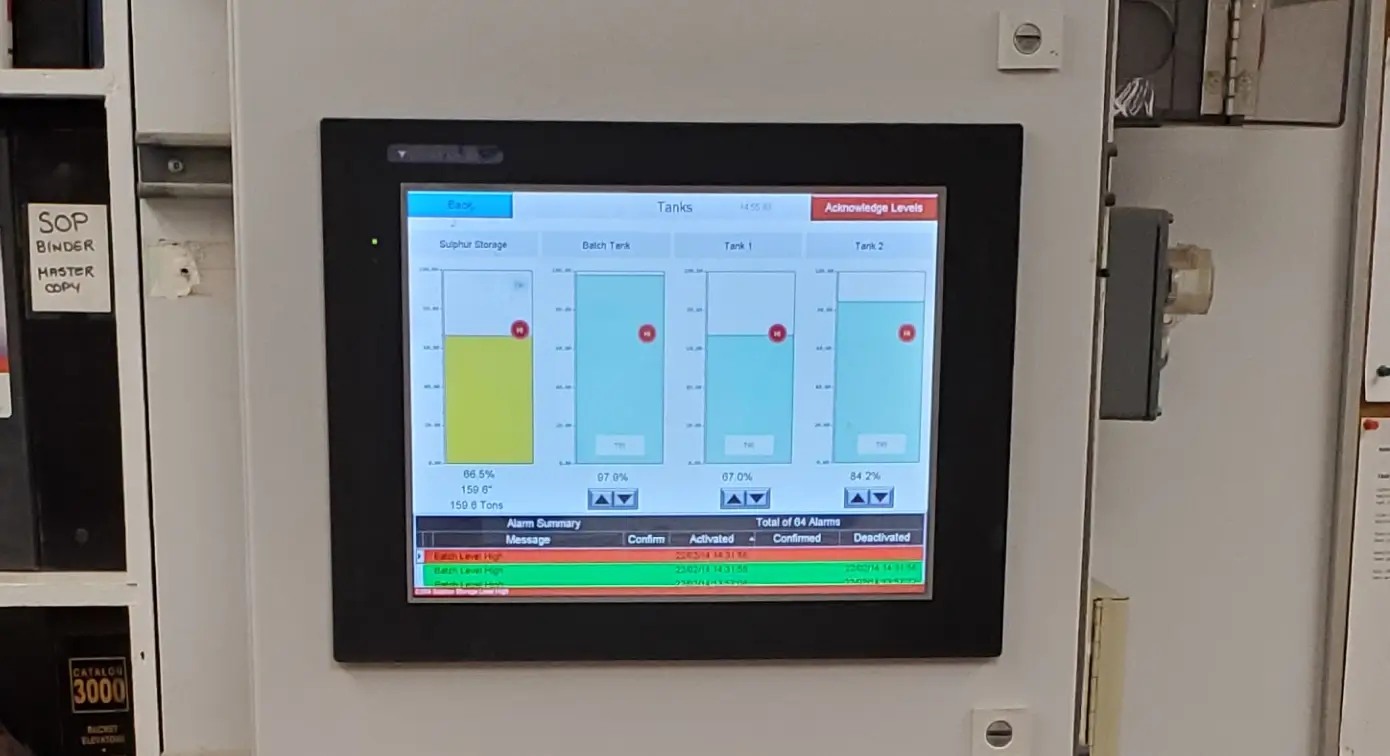

Implementation of a computer system that automates the process of monitoring and transferring grain between bins based on capacity, significantly reducing the need for manual intervention and improving safety.

Advanced Monitoring

Installation of OPI grain sensors to continuously monitor the temperature and moisture of the stored grain, ensuring optimal conditions are maintained for grain preservation.

Seed Cleaning

- Automated monitoring of inventory levels in each bin.

- Installation of speed controls on augers, conveyors, and elevator legs.

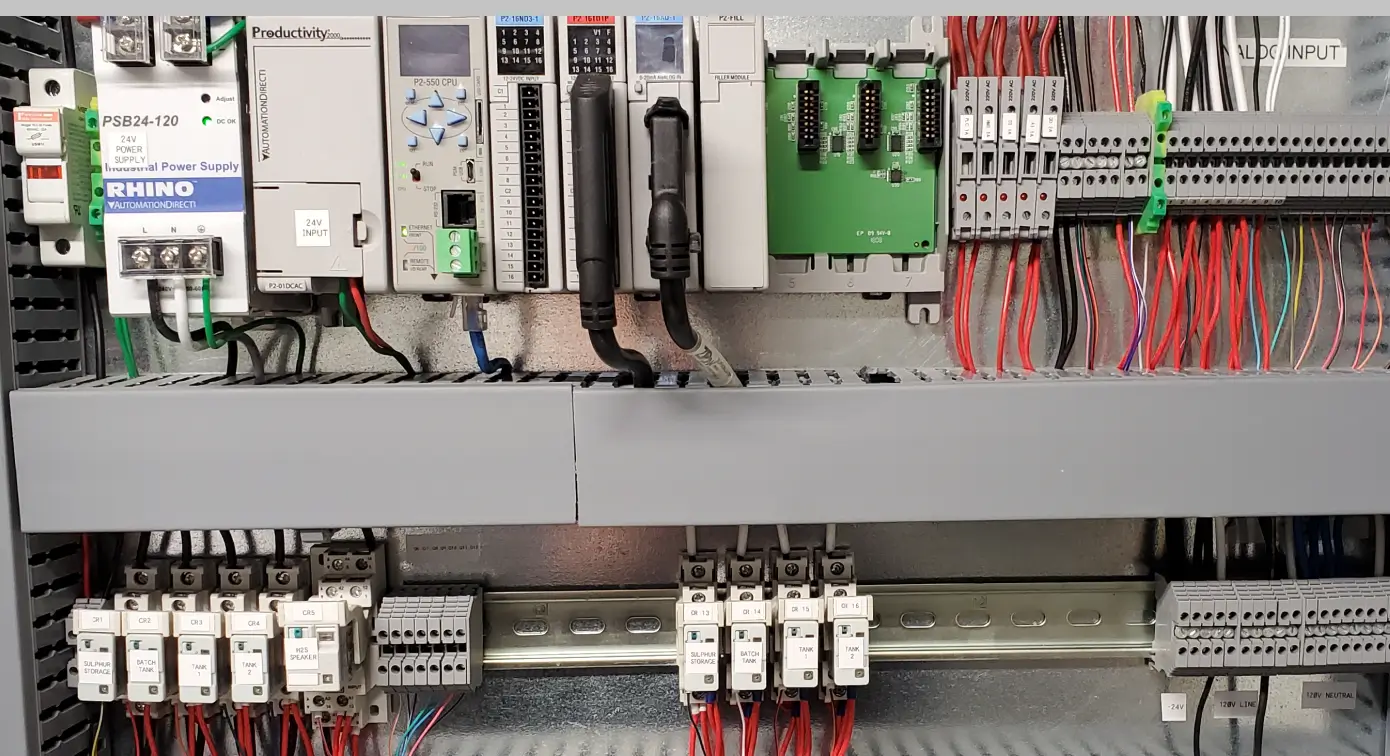

- Development of a PLC program and user panel for efficient grain handling.

- Real-time inventory management and improved accuracy.

- Enhanced safety and elimination of manual checking hazards.

- Prevention of overfills and automatic shutdown during equipment malfunctions.

- Increased productivity and operational efficiency.

Tell Us About Your Project

Challenges in Grain and Seed Handling

Reducing Operational Costs

Outdated machinery and manual processes are driving up labor expenses and slowing down productivity. Automating grain handling reduces energy waste, minimizes labor costs, and improves overall efficiency.

Improving Safety & Space Efficiency

Traditional grain augers take up valuable space and create safety risks. Upgrading to automated conveyor systems provides a safer, more streamlined solution that reduces workplace hazards and maximizes operational space.

Gaining Better Control Over Inventory & Quality

Manually monitoring grain moisture levels and storage conditions is time-consuming and leaves room for error. Integrated automation solutions provide real-time data, ensuring precise inventory control and optimal storage conditions to prevent spoilage.

Enhancing Seed Cleaning Efficiency

Outdated control systems make it difficult to monitor seed levels and maintain consistent processing speeds. Reliable automation ensures precise level sensing, improved speed control, and easier servicing—eliminating delays caused by unresponsive equipment installers.

Designed for Your Operation, Not Someone Else's

Off-the-shelf setups often fall short. That’s why we build systems that are truly custom – down to the wiring, panel configuration, and automation features.

We work directly with you and your team to assess:

- Crop types and volumes

- Equipment already on-site

- Site layout and space

- Power supply and load

- Safety and expansion plans

Every component, from conveyors to control panels, is planned around how your farm actually works – not a brochure layout.

What Goes Into a Smart Seed Handling System

Below is a basic breakdown of what a full-featured seed handling system might include. Of course, every setup is different – but these are the elements we often design, wire, and automate:

Component | Purpose | Custom Options Available |

Conveyors & Augers | Move the seed quickly with minimal breakage | Variable speed, enclosed or open |

Seed Cleaners & Treaters | Clean and prep seed for storage or resale | Integrated controls, automated flow |

Storage Bins & Hoppers | Hold grain safely between handling steps | Level sensors, temperature monitoring |

Control Panels | Central brain of your seed system | Custom-built in-house by Current Group |

Automation & Sensors | Monitor, report, and manage system flow | PLCs, alarms, wireless data integration |

Safety Systems | Keep crews safe during the operation | Emergency stops, motor protection |

When you work with Current Group, we help you select, install, and automate the right components to make seed handling simple, safe, and reliable.

Can Automation Really Make a Difference

Even basic automation like load-out controls or bin level monitoring can save hours of work per week – and prevent costly mistakes.

How Long Does Installation Take

That depends on the system’s size and complexity. We’ll give you a clear timeline and stick to it – because we know downtime during seeding or harvest isn’t an option.

What Makes a Seed Handling System “Custom” Versus Standard Equipment?

A custom seed handling system is built around how your farm operates − not a one-size-fits-all setup. That means it’s designed based on your crop types, bin layout, equipment, power supply, and day-to-day workflow. You get exactly what you need, without wasting space, energy, or time.

How can Better Seed Handling Reduce Crop Loss?

Moving and storing grain the wrong way causes cracking, spoilage, or heat buildup in bins. A well-designed seed handling system uses smoother transitions, enclosed conveyors, and precise speed controls to protect grain quality from start to finish.

Is Automation in Seed Handling Just for Big Farms?

Not at all. Even mid-sized farms can benefit from automating basic tasks like bin level monitoring or conveyor shut-offs. A smart seed handling system can grow with your operation, so you don’t have to overhaul everything when you expand.

Smart Handling, Less Hassle

You don’t need to be an expert in automation to improve efficiency—we handle that for you. From automated handling and conveyor systems, our solutions make moving, storing, and managing grain, seed, fertilizer, and feed easier, safer, and more reliable. We help reduce labour costs and optimize energy use so your operation runs smoothly. Whether it’s upgrading the power supply, improving the lighting, or full system automation, we customize everything to fit your needs, so you can focus on your operation while we handle the details.

Energize your grain, seed, feed, and fertilizer handling systems with Current Group.

PLC Control Systems

Control Room Monitoring

Level Sensors

Conveyor Speed Sensors

Conveyor System Control

Elevator Systems

Weigh Stations

Facility Lighting

Maintenance Services

Design Build Services

Grain Aeration Fans

Grain Dryer Automation

Work With a team That Gets It

Seed handling isn’t just another job for us – it’s part of the bigger picture. We’ve worked on everything from single-bin automation setups to full grain handling facilities with climate control and wireless remote access.

Our team doesn’t just install – we design, wire, test, and support. That means your system is ready when you need it and backed by people who understand the work.

Maximize your farm's effeciency with custom electrical solutions. Let's talk

Whether you’re upgrading an old setup or building from scratch, Current Group brings the hands-on experience and reliability Western Canadian farmers trust.

Let’s build a seed handling system that works the way you do

Tell Us About Your Project

Client Success Stories

The Major Benefits of Electrical Automation

Nearly one-third of all major businesses have automated at least one function in 2021. As more and more companies are looking to optimize their operations,

Sulphur Storage Radar Level Sensors System

Current Group works to make companies safer and more efficient in the agriculture industry by designing and installing radar level sensors in storage bins. Through

Meat Mixing Food Production Engineering

The industrial electrical team at Current Group are experts providing food production engineering services. We have helped numerous food processing facilities put together mechanical and

Frequently Asked Questions

If you’re dealing with bottlenecks, damaged grain, or too much manual labour, it’s likely time for a smarter system. Many Alberta farms outgrow their older setups as they expand.

Customization means the system works with your layout, crop types, and workflow. You’re not forced to adapt to generic equipment that doesn’t suit your farm.

Absolutely. Many farmers start with essentials like a control panel or conveyor, then add cleaners, treaters, and automation as the budget and operation grow.

Yes. We often work with Alberta farms that have older buildings or bin yards. We design systems to fit the space, power supply, and existing infrastructure.

In most cases, yes. A custom electrical control panel is essential to manage safety, power loads, and automation for all system components

Definitely, automation and system design reduce the need for extra hands during peak times and prevent slowdowns caused by manual tasks.