The Problem

In a move to improve their energy efficiency and sustainable farming practices, a leading hog producer based in Southern Alberta reached out to Current Group for innovative agricultural solutions. Animal health is a centric value of this producer, and they wanted to install advanced climate control technology that maintains a comfortable climate for the pigs while reducing energy consumption at the same time.

A high-efficiency ventilation system ensures a pig barn’s healthy and productive environment. The smart ventilation system included intake fans, wall curtains, exhaust fans, interior circulation fans, and heating systems.

The old system would run automatically based on programmed set-points but did not offer environmental monitoring, power, or equipment run-time data logging, so there was no way to evaluate the performance of the system. They knew there was a better way, and Current Group had the experience to help them with cutting-edge agricultural technology.

The Solution

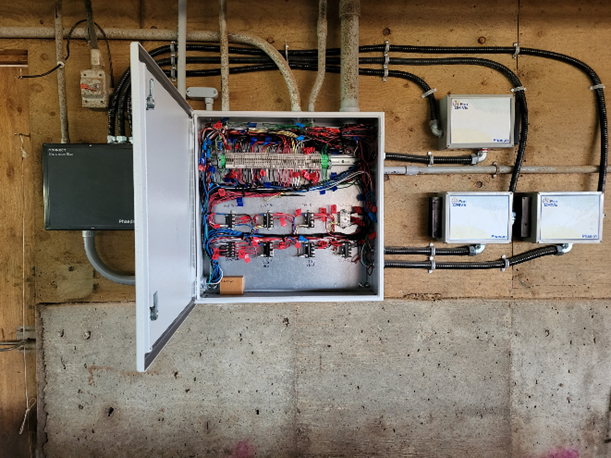

After reviewing the current system, it was decided to install the Phason AutoFlex Connect climate control system in the barn. This automated control system could data log environmental parameters, power consumption, and equipment run-time. The hog barn design was divided into two sections, with a PLC controller looking after each section.

These PLC control panels gathered information from temperature and humidity sensors installed throughout the barn section by automatically adjusting air ventilation components to control the climate of that section.

If the temperature or humidity increased above the desired set point, the PLC first turned on the exhaust fans and power-operated ceiling inlet fans to provide minimum and mid-range ventilation. If the PLC controller is unable to keep the barn environment within acceptable parameters, the system switches off power ventilation and over to natural ventilation by opening/closing side wall curtains to keep the interior barn environment as close to room setpoint as outside conditions permit. The most significant energy benefit results from having the data and information so the controller only turns on the systems needed based on information received by the sensors. This hog producer can now save on energy costs from unnecessary heating and cooling cycles in the barn.

Services Provided

After reviewing the barn’s existing system, Current Group discovered most of the previous wire feeds and cables could be reused, which was a significant cost saving to the customer. The existing electrical control panels were rewired and properly labeled to help troubleshoot any problems that may occur down the road.

The automated air ventilation system allowed the barn workers to focus on caring for the pigs and not worry if the system was wasting energy.

Having Current Group integrate this agricultural ventilation technology ensured the producer kept the company’s core value of “keeping our pigs healthy.”