Background

Firefighting water pumps are essential components of a town’s fire protection infrastructure, ensuring that firefighting efforts can be carried out effectively, efficiently, and in compliance with safety regulations. They provide a dedicated and high-pressure water supply for firefighting, helping to safeguard lives and property in the event of a fire.

The fire water pump house provides a reliable and high-pressure water supply dedicated to firefighting efforts. The pump house is equipped with specialized pumps that provide sufficient water supply with high pressure and flow rates to extinguish fires quickly and efficiently.

In the event of a fire, access to water is crucial, so municipalities must ensure that the fire water pump is always available to supply water to the fire hydrant.

The Problem

Kneehill County, one of our good customers, reached out to us to help them with a problem at their fire water pump house in the hamlet of Swalwell.

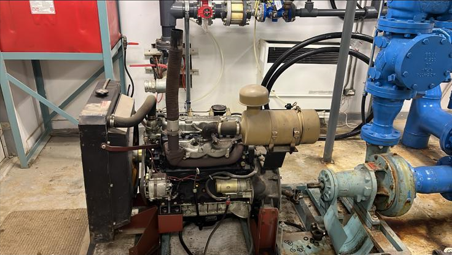

The County was concerned with the reliability of the diesel engine that was connected to the fire water pump. The diesel engine was over 40 years old, expensive to maintain, and difficult to find parts for. The main concern was if the engine didn’t start, they wouldn’t have water at the fire hydrants to fight fires. They wanted to replace the pump with a reliable pump driver that they could count on.

The Solution

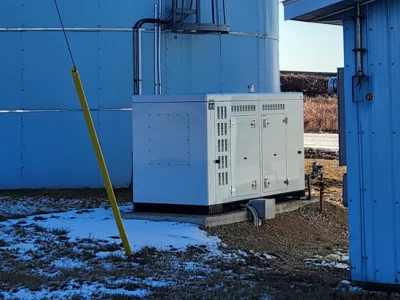

It was decided to replace the old diesel engine pump driver with an electric motor and a Simson-Maxwell standby emergency diesel generator in the event of a power outage. The main power feed also needed to be upgraded to a 200 amp service because of the large horsepower motor.

Services Provided

When the County approached us with the problem we told them that we could help them with the design, electrical installation and removing the old diesel engine and fuel tank. We also looked after coupling the new electric motor to the pump so they only had to deal with one contractor. The County really appreciated this because it made managing the project easier.

The County wanted to use a Simson-Maxwell power generator because they used them at other locations but needed Current Group to select the right size. Once the electric pump motor and generator were selected, Current Group designed and sourced all the electrical components for the project. The main component in the system was the automated transfer switch. Automatic transfer switches detect power outages and switch to the backup generator automatically. This ensures that your backup power system can activate quickly during an outage, minimizing disruptions. The transfer switch also prevents back feeding electricity generated by the backup generator into the electrical grid.

The Allen-Bradley VFD control panel and Eaton transfer switch were selected because of their automation and remote communication capabilities. We recognized an opportunity to provide remote monitoring and control to help the County maintain the pump house. The Eaton transfer switch was an ideal component because it combined the function of the transfer switch and meter base all in one panel. This compactness worked perfectly because the pump house was small and didn’t have a lot of room for big electrical cabinets.