Replenish Nutrients, based in Beiseker, Alberta, is a leader in regenerative agriculture technology and organic-based fertilizer manufacturing. Their products help farmers restore soil health while promoting sustainable agriculture. After proving their product’s value in pilot-scale production, the company faced a critical challenge — scaling operations while modernizing their aging, manually operated processing facility. To meet these goals, they partnered with Current Group for a complete electrical and automation upgrade.

From Manual to Modern: The Push for Plant Modernization

The project’s objectives were clear: automate operations, reuse viable equipment to control costs, increase efficiency, reduce downtime, enhance safety, and provide centralized production control. The original facility, designed for prototyping, was not suited for full-scale production. It suffered from frequent dryer blockages due to overloading, labor-intensive manual product routing, confined space entry hazards, inventory shortages that delayed liquid blending, and the need for up to three operators per shift.

For agricultural producers facing similar issues, these challenges are a reminder of how agricultural automation solutions can directly improve productivity and safety.

Strategic, Ground-Up Rebuild with Industrial Electrical Expertise

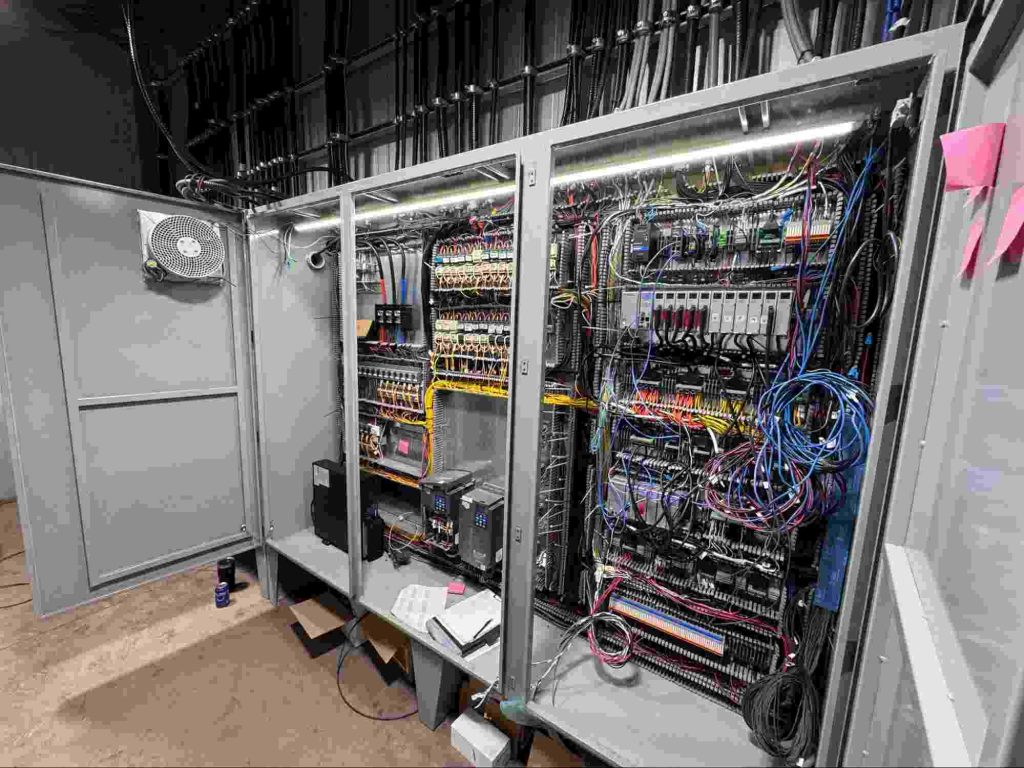

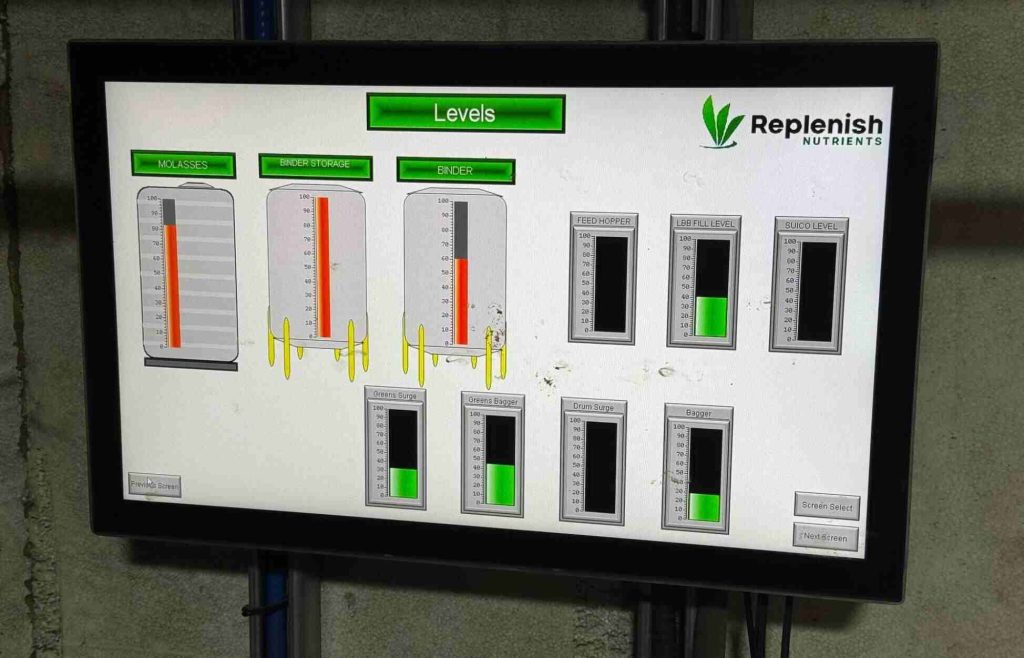

Current Group began with a comprehensive plant audit, selectively dismantling infrastructure to salvage usable components. We developed CSA-compliant electrical systems and constructed custom motor control centers (MCCs) and control cabinets. Using Vega Instruments, the team implemented automated level monitoring, dryer load alarms, VFD motor control, and initiated a smart digital distribution system for precise routing.

This integration enabled:

- Preemptive dryer blockage prevention through alerts

- Real-time inventory monitoring with remote access

- Centralized SCADA-style dashboard for production visibility

- Computer-controlled routing for flexible distribution

- Reduced confined space risks via automation

Measurable Results in Process Automation for Agriculture

The results were immediate and measurable. Dryer downtime dropped from 6–8 hours per blockage to under one hour. Inventory management shifted from manual tracking to a live, remote-access system. Labor requirements are now on track to drop from three operators to just one per shift.

Metric | Before Upgrade | After Upgrade |

Dryer Downtime | 6–8 hours per plug | <1 hour with alerts |

Inventory Management | Manual tracking only | Real-time remote access |

Labor Requirements | 3 operators/shift | Targeting 1 operator |

Production Visibility | None | Centralized dashboard |

Routing Flexibility | Manual gates | Computer-controlled |

Confined Entry Risk | High | Greatly reduced |

By integrating process automation for agriculture, Current Group not only improved reliability but also provided a scalable platform for future growth.

A Model for Sustainable Agricultural Operations

This project demonstrates how fertilizer plant automation can transform operations. By designing and implementing robust control systems, Current Group addressed immediate challenges and positioned Replenish Nutrients for long-term success.

For other agricultural and industrial facilities in Western Canada, this case study proves that plant modernization services can deliver higher output, lower labor costs, reduced downtime, and safer operations, without replacing every piece of equipment.

Current Group’s deep expertise in automation, electrical design, and operational efficiency ensures producers are ready to meet growing market demands with confidence. Contact Current Group to discuss how we can modernize your agricultural or industrial facility.