How do farmers control heat and humidity in livestock and feed storage areas?

When it gets hot and humid inside the barn, animals feel it first. Pigs stop eating, birds pant, and stress levels rise. But livestock aren’t the only ones affected. Grain bins start sweating. Feed mills slow down. Moisture seeps into stored products, and their quality begins to decline. Equipment under such strain doesn’t last long.

This is where climate control systems for farms make a difference. These systems track temperature and humidity, automatically running fans, heaters, vents, and other components to maintain a steady environment. Instead of reacting after problems arise, the system adjusts in real-time. That keeps animals comfortable, maintains their good condition, and protects your equipment.

What problems happen when a farm climate isn’t controlled?

Without the proper controls in place, barns and storage buildings become unpredictable. In the summer, trapped heat can spike in the afternoons. In winter, moisture accumulates due to animal respiration or inadequate airflow. For grain storage, that leads to spoilage, crusting, and reduced feed value. In processing areas, machines overheat or corrode

For livestock, the result is slower weight gain, feed refusal, and higher mortality. For stored grain or bulk feed, it’s a drop in quality that hits your bottom line. And for your motors, augers, and panels, it means more downtime and more costly replacements.

Climate control systems for farms help prevent this by managing air movement, temperature, and moisture in a way that supports all parts of your operation—animals, grain, and infrastructure.

What’s included in a farm climate control system?

Current Group customizes every setup based on the type of facility. Whether you’re managing hogs or maintaining a grain-handling site, no two farms are the same. That’s why each system is tailored to your building layout and equipment needs.

A typical climate control system for farms includes:

- Temperature and humidity sensors are placed in critical zones (animal pens, feed storage, bin tops)

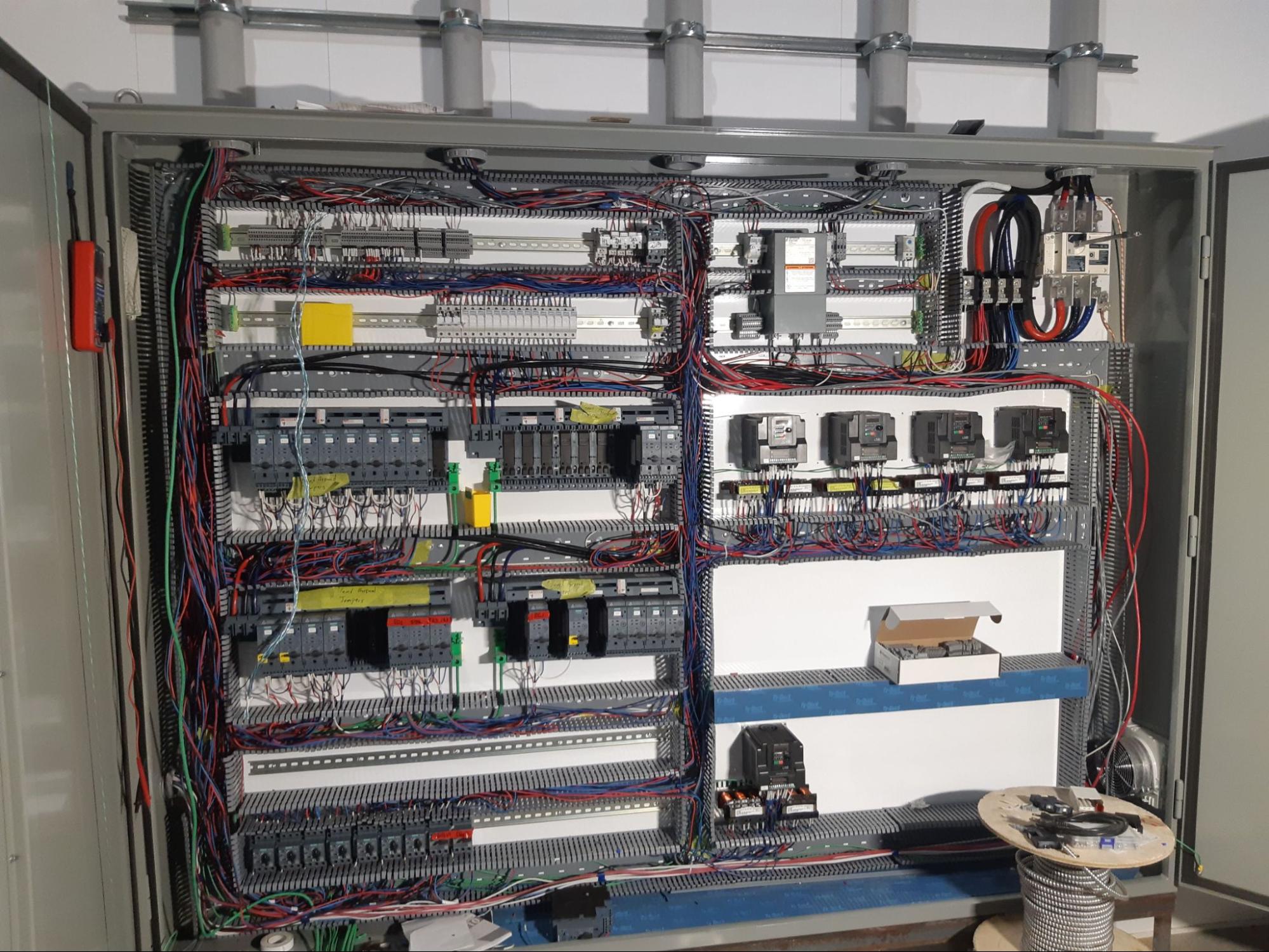

- MCC, VFD, and PLC panels to automate motors and cycle ventilation or heating

- Automated fans, inlets, and heaters for livestock and storage buildings

- Alarms for sudden temperature or moisture changes

- Optional remote access and alert systems for off-site monitoring

These systems keep barns balanced and ensure your grain or feed storage doesn’t suffer from uncontrolled heat or condensation.

How do these systems protect feed and equipment?

Stored grain and feed are sensitive to temperature swings. Too much heat and moisture can spoil a batch in just a few days. Even when it’s dry outside, the wrong indoor conditions can create mould pockets or lead to crusting. Moisture also causes augers, belts, and motor bearings to wear out faster.

Climate control systems for farms reduce the need to chase down problems later by keeping air moving and regulating humidity. For equipment, automated systems reduce run times and wear by efficiently managing motor speeds. That saves money on power and replacement parts over the long term.

What are the standards for barn and storage air quality?

Whether you are raising livestock or managing a high-value crop input, there are air quality and moisture standards to meet. For animal health, provincial and national welfare codes outline temperature and ventilation minimums. For grain and feed storage, moisture thresholds protect against spoilage and contamination.

By using climate control systems for farms, you’re able to stay ahead of these standards. The system helps you catch problems before they escalate and creates a stable, compliant environment without relying on manual adjustments.

Are climate control systems hard to manage?

These systems are built with the operator in mind. Once installed, day-to-day use is straightforward. You can monitor everything from a single control panel or even your phone, if remote access is set up. Alerts are simple and can be handled by your crew without needing a specialist every time.

Current Group installs and supports climate control systems for farms across Alberta and Saskatchewan. We utilize hardware designed for harsh environments—such as dust, moisture, and temperature swings—and our local team is available to assist if anything goes wrong.

What types of farms are using these systems?

We’ve installed these systems in finishing barns, layer barns, and feed facilities, where temperature and humidity were once constant challenges. Many farms start by automating ventilation in their livestock buildings, then expand into feed rooms and grain bin monitoring as they see the benefits.

Climate control systems for farms are especially valuable on mixed operations where you’re managing both animals and inputs. Keeping pigs comfortable and grain dry shouldn’t be two separate jobs. A well-built control system can handle both.

How do I get a climate control system installed?

It starts with a walk-through. We visit your site, review your barn and storage areas, and identify where climate control can make the biggest impact. From there, we design and install a system that’s right-sized for your operation. If you’re losing feed to moisture, replacing burnt-out motors, or constantly adjusting fans by hand, it’s time for a better solution. Book a walk-through with Current Group. Let’s help you take control of heat, humidity, and everything in between.