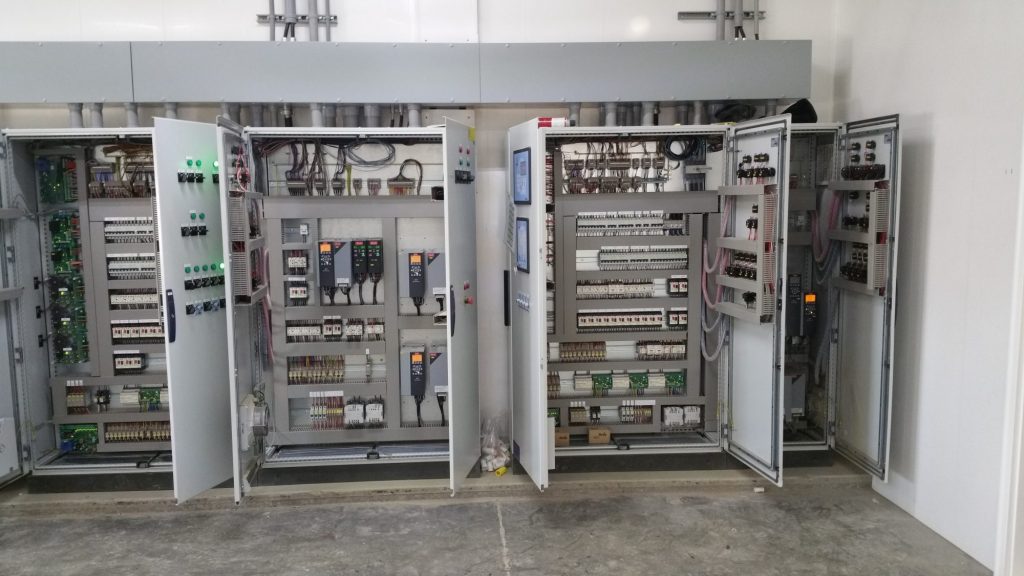

PLC Control Panels

Home » Services » Electrical Panels » PLC Control Panels

What Is a PLC Control Panel?

A PLC (Programmable Logic Controller) control panel contains electrical components such as relays and switches, that run factory machines or processes in single or multiple networks. They are small but powerful computers that are integrated into your control panel and are capable of tracking and analyzing any process with the information available at your fingertips. PLCs are easy to operate, and they work to boost your facility’s output while also improving energy efficiency and decreasing costs.

PLC’s are also advantageous for numerous reasons, including, but not limited to:

- the programming can easily be changed to adjust to new facility needs, as opposed to having to switch out wiring or hardware

- their ability to communicate with other equipment such as MCC’s, VFD’s, HMI software, and data acquisition systems

- their high level of reliability in keeping all processes in your facility running efficiently

- remote control – PLCs are easily connected to the internet allowing remote control by desktop or smartphone app

- the ease of troubleshooting – Current Group offers a 24/7 maintenance service in the case any repairs or troubleshooting are needed.

PLCs can be applied in any instance where electrical automation is implemented. For example, one of our past projects for the farming industry involved installing a climate control system in a new broiler poultry barn. Working closely with the client and the equipment manufacturer Fancom®, we installed a complete climate and feeding solution that controlled ventilation, temperature, humidity, lighting, and watering systems.

PLCs are commonly used in the following areas:

- Food Processing

- Livestock Production

- Equipment Manufacturing

- Agriculture Grain & Fertilizer Handling

- Oil & Gas Production

- Coal Mining

- Aggregate Crushing & Handling Operations

- And much more!

What is the Difference Between a PLC Electrical Panel and a Traditional Control Panel?

A PLC electrical panel includes a programmable controller for digital automation, allowing for flexible programming and remote access. Traditional panels often rely on hard-wired relay logic, which lacks the adaptability and advanced diagnostics found in automation electrical panels.

Can PLC Control Panels Integrate With Existing Systems?

Yes, most modern PLC control panels are designed for easy integration with existing systems such as HMIs, SCADA software, VFDs, and more. Current Group ensures seamless integration of industrial PLC control panels into your operations for improved performance.

How Do PLC Panels Improve Energy Efficiency and Reduce Downtime?

Automation control panels with PLCs monitor and optimize process variables in real-time, ensuring systems run only when needed, reducing energy waste. Additionally, built-in diagnostics and remote monitoring minimize unplanned downtime and service costs.

Custom PLC Control Panels

Manufacturers commonly use PLCs to control the operation of the equipment they build, and Current Group uses this off-the-shelf technology to solve our customer’s problems. But on occasion, there isn’t an off-the-shelf solution, and that’s when we program a PLC with a custom program to suit your application. If you feel that your business or facility is in need of more advanced control of the operations, an improved Human-Machine Interface (HMI) or the desire for a more cohesive, universal control of your manufacturing systems, reach out to Current Group for a No-Obligation Quote on a Custom PLC Panel!

Frequently Asked Questions About PLC Control Panels

A PLC panel is an enclosure that houses a programmable logic controller (PLC) and other electrical components used to automate machinery and processes. It acts as the brain of your system, controlling inputs and outputs for reliable performance.

A PLC control panel runs logic-based commands to automate equipment. It processes data from sensors, switches, and timers, then sends signals to motors, valves, or relays to manage operations safely and efficiently.

PLC electrical control panels are widely used in agriculture, manufacturing, food processing, utilities, and oil and gas. Anywhere automation is needed for pumps, conveyors, motors, or climate systems, a PLC panel is a reliable solution.

An industrial PLC control panel is built to handle rugged, high-demand environments. It’s typically larger, has more I/O capacity, and includes advanced safety and communication features for complex systems and regulatory compliance.

A custom PLC electrical panel ensures that every component fits your specific process. Off-the-shelf panels often fall short when dealing with specialized equipment, layouts, or safety needs. Custom builds reduce integration issues and future downtime.

A good automation control panel is one that’s well-organized, easy to troubleshoot, and designed with future growth in mind. At Current Group, we build panels with clean wiring, proper labeling, and room for expansion.

Yes. PLC panels can be built with NEMA-rated enclosures, cooling fans, and moisture or dust protection. For wet or outdoor settings – like barns, food plants, or remote industrial sites – we customize builds to handle the conditions.