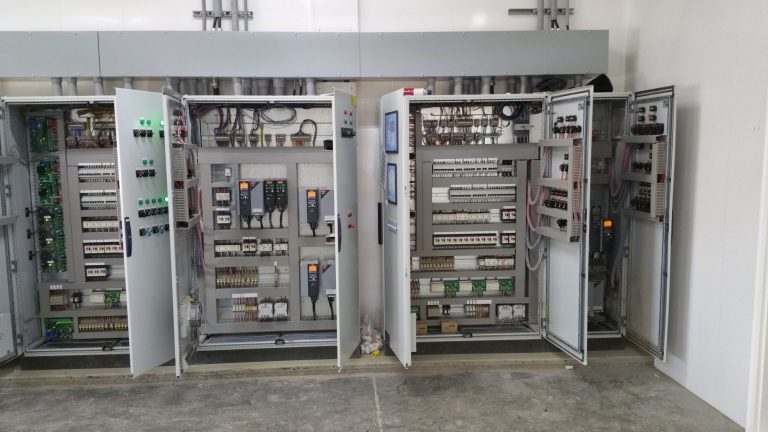

Electrical Panels

Industrial equipment and machinery require defined functions and orderly control to achieve process goals, and as such electrical control panels are needed to carry out these critical functions. Each business has specific needs, and our custom electrical control panels are fabricated to meet those unique specifications. Each control panel is designed and built for ease of use and effectiveness so that our clients never need to worry about performance and efficiency.

What are Electrical Control Panels For?

Electrical control panels are used to house and organize electrical components such as switches, relays, circuit breakers, and other devices that control and monitor electrical systems. They serve the following purposes:

- Control and monitoring. They provide a centralized location to control and monitor the operation of electrical equipment and systems.

- Safety. Electrical control panels ensure safe operation by housing components like circuit breakers that protect against overloads and faults.

- Automation. They facilitate automation by integrating control devices that manage processes and operations automatically.

- Organization. Control panels help in organizing electrical components and wiring, reducing the risk of errors and simplifying maintenance and troubleshooting.

- Customization. They can be customized to meet specific operational requirements and to accommodate the layout and needs of different applications.

Electrical control panels are essential for ensuring efficient and safe operation of electrical systems across various industries, from manufacturing and industrial facilities to commercial buildings and infrastructure projects.

Control Panel Fabrication

Control panel fabrication involves the meticulous process of designing, assembling, and installing customized electrical control panels to meet specific operational requirements. This process integrates various components such as circuit breakers, switches, relays, meters, and control devices into a unified system.

The fabrication begins with detailed planning and design, where engineers and designers assess the functional needs and layout constraints of the control panel. This stage includes selecting suitable materials, determining the optimal size and configuration, and considering factors like environmental conditions and safety standards.

Once the design is finalized, skilled technicians proceed with the assembly phase. This typically involves precision wiring and mounting of components within the panel enclosure. Each component is carefully positioned and connected according to the wiring diagrams and specifications to ensure proper functionality and reliability.

Quality assurance is a critical aspect throughout the fabrication process. Technicians conduct thorough inspections and tests to verify the integrity of electrical connections, the accuracy of component placements, and compliance with regulatory requirements. This ensures that the fabricated control panel meets performance standards and safety regulations before deployment.

After fabrication, the control panels may undergo additional customization to integrate specific control logic, programming, or communication interfaces tailored to the operational needs of the client. Installation and commissioning services are often provided to ensure seamless integration into the client’s facility or system.

Overall, control panel fabrication combines expertise in electrical engineering, precision assembly, and quality control to deliver bespoke solutions that optimize operational efficiency, enhance safety, and support the reliability of electrical systems in diverse industrial applications.

Benefits of Electrical Control Panels

The electrical control panels offer several advantages in industrial environments. It simplifies the monitoring and control of electrical systems in specific spaces, helping operators to efficiently achieve automation goals. Panels are highly adaptable to industry-specific requirements, providing flexibility without design constraints.

By providing real-time data and the ability to quickly adjust conditions, the control panel increases the reliability of electrical systems. It integrates the control of complex industrial systems into a single device, which not only simplifies operation but also significantly reduces costs.

Available for indoor and outdoor applications, these panels are weatherproof and assist operators in the field by providing the necessary input even in emergencies. They are equipped with safety features, including hazard and fire protection, to ensure that personnel can work safely.

The integration of control, monitoring, and inspection functions into a single panel reduces overall plant operating costs. This centralized control also minimizes the likelihood of system failures, improving operational stability.

Electrical control panels simplify troubleshooting by providing comprehensive monitoring of equipment and lines, making it easier to quickly identify and correct problems throughout the system.

Control Panel Solutions in Alberta

Modern control panel solutions include:

- PLC Control Panels: Programmable Logic Controller panels (also known as PLC control cabinets) include the PLC, relays, switches, and various electrical components required to run a factory machines or process in single or multiple networks.

- VFD Panels: Variable Frequency Drive panels include a frequency conversion device that offers adjustable speeds and power outputs, allowing the system to conserve energy as needed.

- MCC Panels: The Motor Control Center panel is used as the primary means for controlling the various different motors needed for a facility’s electrical system on various frequencies.

- Power Distribution Panels: Ensure that the energy that you need to power your facility is distributed efficiently while reducing unnecessary cabling throughout the building.

- Marshalling Cabinets: Located between the PLC or DCS cabinet and junction boxes, marshalling cabinets act as an interface and termination point by grouping input/output connections.

- Relay Protection & Control Panels: Monitor and protect your electrical systems by detecting overloads, short circuits, and other potential issues in your equipment and automation.

For industries that require complex electrical systems to maintain consistent production, a custom-designed electrical control panel will likely be needed. The design of the panel will depend upon the complexity of the system it operates. Indicators that you might need a custom panel design include a need for more advanced control of operations, a need for improved HMI (user interface that connects you to the system, machine, or device), and a desire for more cohesive, universal control of your electrical systems.

Electrical Control Panels That Actually Work for Your Operation

Most electrical control panels are designed for general use – not for your equipment, layout, or day-to-day demands. At Current Group, we design systems that work with your setup, not against it.

Whether you’re managing grain handling, food processing, or industrial automation, your panel should enhance performance, not create workarounds. We deliver electrical control panels that are clear to operate, built to last, and ready for the real-world conditions of your facility.

You get smarter control, better integration, and fewer problems down the road – all from a team that understands your industry inside and out.

Control Panel Fabrication Done Right the First Time

When you need a panel, you don’t need delays, vague specs, or one-size-fits-all solutions. Our control panel fabrication process is handled entirely in-house, which means no outsourcing, no miscommunication, and no waiting on third-party suppliers.

We handle every part of the job:

- Custom design based on your electrical and operational requirements

- Fabrication and wiring to CSA-certified standards

- Full testing and quality assurance before delivery

From start to finish, it’s our team, our tools, and our standards. That’s how we ensure your panel shows up ready to perform – no guesswork required.

Control Panel Solutions That Put Your Priorities First

Every site is different. That’s why every panel we build is different, too. Our control panel solutions are tailored to fit your priorities – whether that’s fast delivery, space-saving design, or seamless integration with your automation systems.

We’ve worked with farm operators, plant managers, and engineering teams across Western Canada who need dependable systems that don’t slow them down. They choose Current Group because we listen, we ask the right questions, and we deliver what they actually need – not what’s sitting on a warehouse shelf.

If you’re tired of adapting your operation to a panel that doesn’t fit, let’s build one that does.

What is the Role of PLCs in Electrical Control Panels?

PLCs (Programmable Logic Controllers) are the brains behind automated systems. A PLC-based electrical control panel can monitor, control, and respond to changes in your equipment automatically − improving precision and reducing operator load.

Can you Integrate my Control Panel with Existing Automation?

Yes. We regularly build panels that integrate with existing automation, sensors, and software systems. Whether you’re adding new equipment or replacing an old panel, our team ensures everything works together smoothly.

Can I Upgrade Just Part of my Control Panel?

In many cases, yes. We can retrofit specific components − like adding VFDs or updating a PLC − without rebuilding the whole system. Partial upgrades are a cost-effective way to extend the life of your electrical control panel.

Electrical Control Panels Maintenance

Maintenance of electrical control panels is essential for ensuring optimal performance and reliability in overseeing specific electric system applications. These panels house intricate structures and electrical components that handle rigorous tasks, necessitating regular upkeep to maintain efficiency.

Effective maintenance of the electrical control panel system involves several key tasks:

- Ensuring clear labeling of all components, wires, and terminals to facilitate understanding for new operators.

- Maintaining clear and separate electric connections to simplify monitoring processes.

- Regularly cleaning dust accumulation from the enclosure and back panels to prevent interference with components.

- Implementing measures to protect the control panel from rust and pest infestation, ensuring longevity and operational integrity.

By adhering to these maintenance practices, professionals will maintain the functionality and longevity of electrical control panels, ensuring that they perform optimally in controlling electrical systems.

Contact Current Group today to request a quote for an electrical control panel custom-built for your facility and production needs at (403) 546-2153.

Frequently Asked Questions

We build electrical control panels for agriculture, food production, manufacturing, energy, and industrial automation. If uptime, safety, and performance matter to your operation, we can build a panel that fits your exact requirements.

Our control panel solutions include everything from initial consultation and design to fabrication, wiring, testing, and delivery. We handle the full process in-house to make sure you get a system that works – no outsourcing, no compromises, and no delays.

Yes. While we primarily focus on panel design and fabrication, our team also supports control panel solutions that involve installation planning and integration. We’ll work with your team or contractor to make sure the panel fits your setup and is ready to go.

We provide post-delivery support including documentation, troubleshooting, and system optimization. If something’s not working the way it should, we’re just a phone call away.

Yes. We specialize in upgrading outdated electrical control panels with custom-built systems that improve safety, performance, and uptime – without forcing a complete overhaul of your infrastructure.

We use only trusted, high-quality components from leading brands. Every panel goes through testing to ensure the materials meet safety, performance, and reliability standards in harsh field conditions.