Rotary Phase Converters

Home » Rotary Phase Converters

Current Group is pleased to be the distributor in Alberta for premium rotary phase converters from American Rotary Phase Converters, a trusted provider of electrical products and tools throughout Canada for over 20 years. American Rotary provides industry leading telephone support for technical, application, and sizing questions. American Rotary stands behind its products with the best warranty in the industry. American Rotary uses premium components to ensure that its products perform for you. American Rotary is a UL Certified Control Panel Builder, and its rotary phase converters are available UL Listed to US and Canadian Safety Standards. American Rotary has partnered with Baldor Electric one of the world’s largest and most respected manufacturers to supply its custom-engineered idler/generators. American Rotary is listed with D&B as well as the Better Business Bureau, and is committed to high ethical and privacy standards.

Innovations in Rotary Phase Converters

For more than 20 years, American Rotary has led the industry in innovation and design. American Rotary has introduced, field-tested, and proven several technologically advanced features which have driven increases in the reliability and precision voltage balancing capabilities of phase conversion unmatched in the industry.

- American Rotary generators are available with a digital controller, which replaces electro-mechanical relays to more reliably and precisely start the phase converter while constantly monitoring voltage and making automatic adjustments when necessary. This industry-changing advancement not only provides critical protection to the starting circuit, induction generator, and equipment, but also balances the voltage so precisely that our phase converter is preferred by high-end equipment manufactures and many regional and state power companies.

- The engineers at American Rotary worked with the engineers at Baldor for over a year designing a custom induction generator for phase conversion, which reduced the inrush current on start-up so drastically (83% reduction…a stock motor requires 600% more inrush) that American Rotary’s induction generator was granted a Soft Start rating, and a resulting reduction in operating cost!

Construction Quality & Banding

American Rotary phase converters as distributed by Current Group utilizes 100% stress-free mounts on all components. Any electrical product that has any components, especially capacitors (usually silver or black cylinder-shaped parts inside the panel), that are mounted with banding of any kind should be avoided. Banding (tension mounting) is an inexpensive way to mount capacitors and other components, but severely shortens their life by causing damage to the outside of the capacitor. Weakening the casing eventually leads to leaking and ultimately, failure.

Warranty

Is there a written warranty? What is the timeline for fixing a problem? Will you need to send the unit back for repairs or can repairs be done locally? Who pays shipping, if needed? Is the motor under warranty? How do you get a 150 pound motor to a service center? How do you get a 600 pound motor to a service center?

In this video, American Rotary demonstrates the basic installation techniques of the American Rotary Phase Converter Panel. The idea is to show how easy it is to install, and also to provide a video reference for our customers. The video is just under 4 minutes long.

Voltage Balance Testing Claims

The load range is very important when verifying voltage balance claims. A claim of 2% voltage balance may be true for a very limited operating condition, but won’t exist for your application under load, even with field adjustments. This is especially true for stock or modified TEFC or ODP motors. American Rotary precision balances all CNC units over 100% load of the phase converter. In addition, American Rotary’s custom Baldor induction generators are wound with ISR magnet wire, which makes them immune to current spikes common in CNC equipment. Some companies offer motors from more than one manufacturer to go with their phase converter panel. However, different brands and different types of motors balance differently.

Induction Generators vs. TEFC & ODP Motors

There are many differences between American Rotary’s Phase Converter Induction Generator and stock or modified TEFC and ODP electric motors. American Rotary has constructed the following table to summarize the most critical differences.

| Induction Generator | TEFC/ODP Motors (Stock or Modified) |

|---|---|

| Designed to deliver superior voltage and current balance required for phase converter applications, and it is 98% efficient | Designed to provide torque for a load on its shaft, making it less efficient, and diminishing its ability to attain precise voltage balance. |

| Soft Start rating granted by reducing inrush current (and operating cost) by 83%. | Requires 600% more inrush current to start and cost more to operate. |

| Manufactured without an exposed rotating shaft. | Manufactured with an exposed rotating shaft that must be removed for safety, which causes physical imbalance, and may cause bearing failure and/or void the motor manufacturer’s warranty. |

| Designed to operate at synchronous speed indefinitely, which means you can safely leave your phase converter running at idle. | Not designed to operate at synchronous speed for long periods without a mechanical load on the shaft. |

| Run quietly and stay cool while optimizing voltage and current balance. | TEFC motors have large cooling fans that produce noise and rob power to stay cool, which further reduces its ability to balance voltage. |

| Manufactured to our specifications by Baldor Electric 100% in the USA. | Manufactured in China (Worldwide Electric, Leeson), Brazil (Weg), and Taiwan. |

Applications Rotary Phase Converter in Canada

Agriculture

American Rotary phase converters are built for the demands of agricultural equipment and applications (augers, compressors, cream separators, silo unloaders, hammermills, pumps, fans, hoists) and are useful for farms located in areas that do not have access to the 3-phase power grid. Phase converters provide reliable and cost-effective phase conversion for any agricultural setting.

Food Service

Phase converters are designed to provide the precision output voltage needed for voltage-sensitive applications such as pizza ovens, regular ovens, rotisseries, ice cream machines, Hobart mixers, wine presses, coffee grinders and other food processing machines.

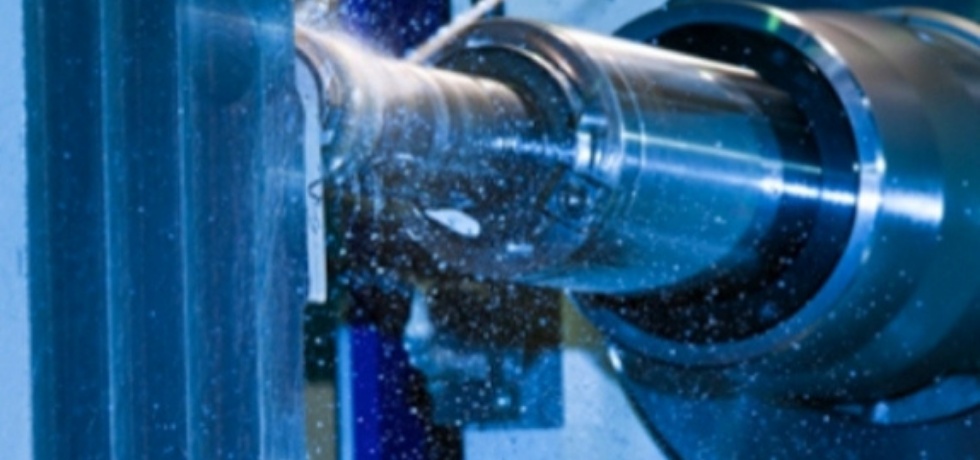

Metalworking

Phase converters are perfectly suited for precision metalworking equipment such as wire EDMs, CNC lathes, CNC mills, and other voltage-sensitive applications. General metal fabrication equipment such as grinders, welders, shears, brakes and benders, are often run on phase converters. Both small, lightly loaded machines and large heavily loaded machines work well with a phase converter.

Industrial

Rotary phase converters convert single phase power to 3-phase power so any shop environment can take advantage of 3-phase equipment, without being burdened by demand charges and expensive installation by the power company. Phase converters are quiet, easy to install, reliable and robust enough to handle the most demanding industrial applications.

Machining

Phase converters meet the requirements of CNC used in metal fabrication by maintaining at least a +/-5% voltage balance. The balanced output of a rotary phase converter means equipment will operate better and longer.

Woodworking

Woodworkers often need to start and run multiple 3-phase machines (table saws, jointers, planers, etc.), sometimes simultaneously. The balanced output of a phase converter allows for the safe operation of very small, lightly loaded 3-phase machinery on the same rotary 3-phase converter as larger, hard-starting equipment.

Order A Rotary Phase Converter in Canada

Why Choose Current Group for Your Phase Converter Needs?

- Expert Guidance: Our experienced team is ready to assist you in choosing the ideal converter tailored to your unique requirements.

- High-Quality Products: We supply industry-leading brands, including American Rotary Phase Converters, known for their durability and efficiency.

- Nationwide Availability: Whether in a bustling city or a rural area, you can count on us to deliver your rotary phase converter in Canada promptly.

- After-Sales Support: Our commitment doesn’t end at the sale—we provide ongoing support to ensure your equipment runs flawlessly.

American Rotary Phase Converters: A Trusted Choice

- Smooth and balanced power output for sensitive equipment.

- Quiet and energy-efficient operation.

- Durable construction for long-lasting performance.

Why Invest in a Phase Converter in Canada?

- Increased operational flexibility.

- Reduced energy costs.

- Minimal downtime for your equipment.

Partner with Current Group Today

Contact Us

Choosing the right equipment can be tough – especially when power reliability affects your daily operations. At Current Group, we help farms, shops, and industrial facilities find the most efficient and durable rotary phase converter Canada has to offer.

Whether you’re upgrading old systems or setting up a new site, we’ll guide you through your options. If you’re unsure where to start with a phase converter in Canada, our team is here to answer your questions and recommend a solution that fits your load requirements and budget. Contact Current Group today – we’ll make sure you get the right setup the first time.

Frequently Asked Questions about Rotary Phase Converter

Current Group

Find Out How Our Clients Save 10%+ On Labor By Implementing Our Easy-To-Use Systems...

...Without shutting down for weeks during commissioning